Take a moment to think about the biggest advancements in logistics. Automated systems and advanced workflows have brought new life to carrier operational excellence and collaboration with shippers. Through data-driven transportation management, carriers can finally become more strategic and tactical, thriving through good and bad times. Logistics automation offers more value via management by exception and making profit-driving decisions for all incoming tenders. Achieving that goal hangs on a carrier’s ability to capture meaningful data.

Market conditions and demand drive carrier profitability. And while logistics automation is believed to be the end-all solution for most, they may fall short of meaningful improvements. But why? Autonomous processes are only as valuable as the data that powers algorithms and decision-making. Failures to capture a larger market view will inevitably lead to missed opportunities.

Over time, missed opportunities result in higher costs in the form of:

Here’s the kicker. Like shippers, carriers can sometimes fail to realize which customers, in this case, shippers, are simply not pulling their weight. Take this example reported by Richard Davis in Supply & Demand Chain Executive, “It’s 7:00 p.m., your warehouse team has just finished their final picks for the evening, your fleet has been loaded based on standard routing calculations, and you’re ready to pack up shop. Then that dreaded moment happens – a member of your sales team calls down to the warehouse: ‘Our best customer needs more by tomorrow, or they’ll go somewhere else.’

However, it turns out that the customer that made your people jump through hoops is, in reality, an underperformer from both a gross margin and gross profit perspective. In fact, unknown to the sales force or anyone else, this “best customer” has been in the bottom quartile of your customer portfolio for several years. Worse, that “critical” sale just cost you more money to process than it produced in profit.”

While that’s an example of a particular warehouse, it has a natural implication for carriers. Remember that carriers are those that actually move freight. Thus, problems in the warehouse with those types of customers could be a harbinger of the same shippers when it comes time to tender a load.

Shippers should add value to carrier operations in the form of demands that are both lucrative and manageable. Logistics automation, including automated freight quotes, can provide a seamless data-sharing benefit. Unfortunately, even automated tenders may still fall well below the real threshold for valuable moves. For that reason, the key to success as a carrier and shipper that rely on logistics automation is to follow the data. Consider the following example.

If an incoming tender has a destination with minimal backhaul opportunities, carriers should price that tender based on the total costs, including the lost revenue that may result from driving empty miles. Ergo, the total cost per mile must be included in the quote.

That’s essential.

Automation is one step in a series of best practices that carriers may apply to maximize logistics automation value. Carriers must collect, analyze and proactively apply data, which “is critical,” says Supply Chain Brain. “Today’s logistics leaders are not only experts at tactical execution. They answer critical questions such as: how will a more responsive network enable growth? Will network investments lower operating costs? If operating costs increase, will sales volume warrant the investment? This process will ensure that you gain the greatest business value given your demand patterns to ensure that the network you design aligns with your company’s commercial model for success.” In other words, logistics leaders must find and apply proactive data management strategies, including:

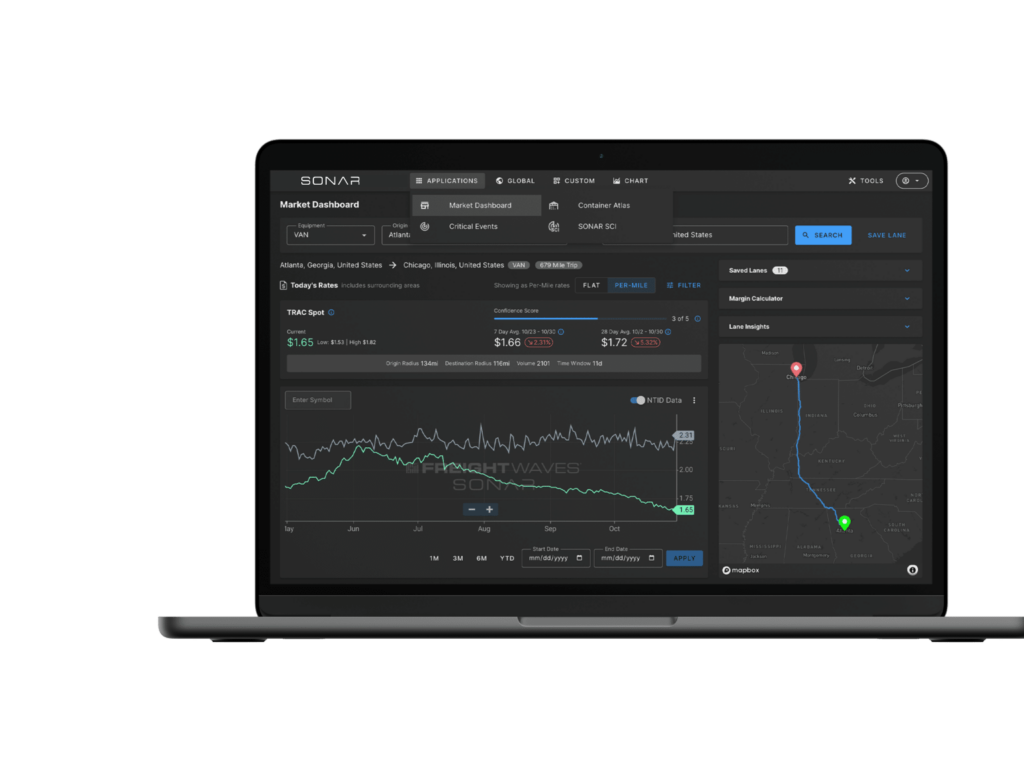

Logistics automation and data integrity are absolute necessities in supply chain advancement. Global supply chains continue to undergo digital transformation. And those that can roll with the punches and apply data will be best prepared for future disruptions. Recognize that fact and begin the process of using real-time freight data to make all decisions. Get started by requesting a FreightWaves SONAR demo or clicking the button below.