A Fortune 500 packaging company has faced numerous challenges over the past few years as raw material prices have risen dramatically, raw material availability was challenged and transportation networks were difficult to manage.

The packaging company was searching for the ability to:

- Identify freight market trends

- Improve negotiations with its carrier base to ensure fair pricing

- Limit service-related delays across its transportation network

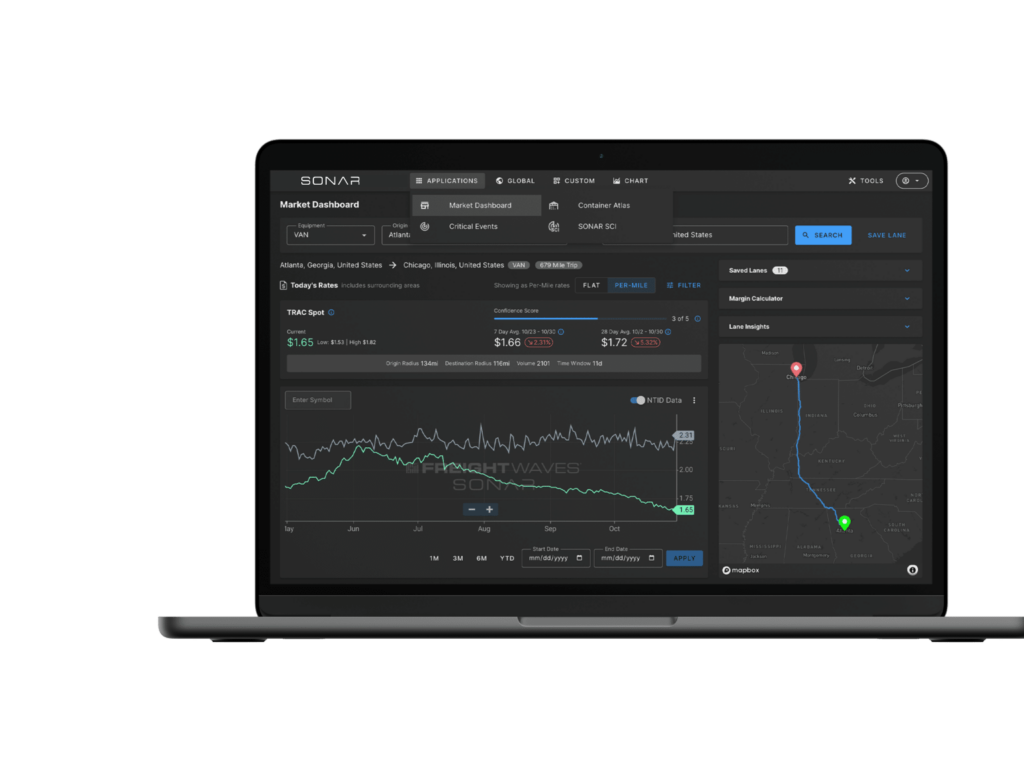

The packaging company turned to SONAR and Supply Chain Intelligence (SCI) platforms to implement the use of high-frequency data along with the guidance from experts into its repertoire.

Through the use of the SONAR and SCI platforms, the packaging company was able to reduce rate increases that its carrier base was searching for by more than half.

Additionally, the packaging company was able to reduce the number of tenders being rejected from over 25% to the mid-single digits before the market turned in the middle of last year.

As the negotiating leverage has continued to shift more in favor of shippers, the packaging company has been able to be proactive in searching for rate reductions in areas that previously have been difficult to achieve, given the geographical challenges that certain markets present.

SONAR and SCI have provided the packaging company’s transportation team with the ability to show leadership how it compared to the general market, identify opportunities for further cost savings and de-risk its transportation network when the freight market inevitably shifts once again.