Grocery supply chains are full of nuances associated with the movement of goods ranging from dry van freight from consumer packaged goods companies to produce from various sources around the world. The result is grocers spend more for transportation than what the market indicates would be a “fair” price.

A regional grocer was searching for a way to:

- Improve transportation purchasing efficiency.

- Reduce overall spending on applicable lanes.

- Mitigate service failures related to rates.

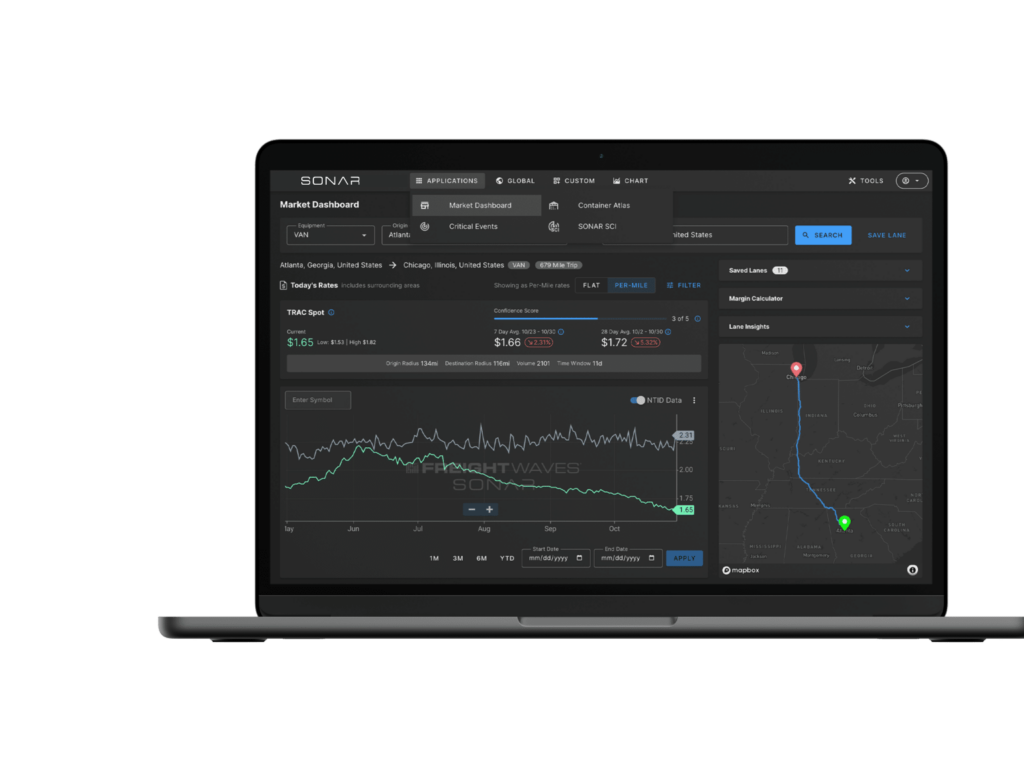

The grocer turned to SONAR and its Supply Chain Intelligence (SCI) platform to benchmark its rates and identify savings opportunities along high-volume long-haul lanes.

At the beginning of the analysis, the grocer, through SCI, discovered that it was paying nearly $140 million more than the current market rate. Overpaying the market was the norm for the grocer due to the nuances, but the grocer was spending more than $15 million more than even the “high” market rate.

The SONAR and SCI platforms highlighted where the company could improve purchasing across its long-haul lanes, leading to network optimization, improved negotiations with truckload carriers and an understanding of capacity changes in the market, and ultimately uncovering ways to reduce transportation spending.

The grocer found that in lanes where it was paying more than 20% above the high market rate, reducing the benchmark rate by 10 cents per mile would generate more than $7 million in savings. Furthermore, if the grocer adjusted the benchmark rates on the lanes where it was paying more than 20% higher than the high market to just 10% above that rate, it opened up more than $50 million in potential savings.