How does your company define success in the supply chain? For shippers, success depends on end-to-end network improvements, according to McKinsey & Company. Shipping analytics tools shine a light on the value of informed freight management. Freight market participants need these top shipping analytics tools in their freight stack.

Tracking shipment status is a core function of advanced shipping analytics tools. Yes, knowing real-time status is great. But knowing when it will be late or missed is better.

Shippers also need a way to look beyond the enterprise’s four walls to understand waste. Wasted warehouse space leads to higher overhead. Yet analytics-driven processes can reduce excess inventory. For example, just-in-time fulfillment models, drop-shipping, and cross-docking avoid wasted space. And they keep inventory levels lean.

Collaborative analytics help the supply chain work together. But modern supply chains are super-complex. Collaboration means parties must share data in real-time. And collaborative analytics provide the information needed to inform everyday conversations. That extends to guiding freight bids too.

For example, market conditions show shippers’ rate trajectories. Shippers can then better understand and work with freight parties to avoid delays.

Transportation only provides a partial picture of an industry. Viewing transportation networks with multi-angled metrics goes a long way to reducing costs. One of these metrics is the Logistics Managers Index (LMI), which SONAR provides users. For instance, shippers see the warehouse use rates via the LMI. Multi-angled views like distribution center wait times help to avoid surprises.

Improved planning through wait time analysis benefits all parties.

Things go wrong in supply chains. That much is always going to be true. Seeing the delays in one part of the network is key to stopping the disruption. That helps shippers avoid excess detention fees by better planning their dock schedules.

Using shipping analytics tools, shippers see across modes. Ocean freight impacts on trucking is another use case. Ocean freight that arrives in a port means opportunities for trucking companies. However, it also may lead to the need to move equipment and assets.

For instance, a shipper may look to move in-house fleets to port cities. Analytics help shippers preempt changes in the market despite the mode. Higher port activity leads to tighter trucking capacity in portside O/D pairs.

Even if a shipper follows all the right steps, compliance can remain an issue. Shippers need to maintain compliance with truckers, carriers and other trading partners. That includes compliance with the inbound freight routing guide and outbound activities. For sensitive shipments, it takes on a new value. Compliance could include routing sensitive shipments faster to a given facility. Thus, companies can move higher-priority freight faster.

An inbound routing guide may need extra sign-offs for delivery after-hours. The most relevant example of this need for added complexity is the pharmaceutical industry.

Delivering a load does not equate to a complete transaction. Only freight payment does. But trucking rate invoice errors are more common than many realize. The problem only grows worse in larger supply chains. The urgency over fast payment amounts to excess freight spend. But again, shipping analytics tools can check everything. They sort through prior quotes, invoices and shipment data to check invoice accuracy.

Shipping analytics tools also provide insight into the lead time. For instance, increased lead time in high-demand markets will lead to higher rates. When freight rates rise in a more valuable aspect of the market, drivers will follow. Then, the cycle becomes self-propagating and stimulates higher rates on spot loads. Knowing volume volatility and market dynamics adds value. Shippers then become more proactive.

For instance, shippers might encourage customers to order earlier.

Analytics also add value post-final mile delivery. Analytics can inform shippers of increased return rates, problems during delivery and more. These analytics help shippers avoid typical e-commerce problems. Leading by example, supply chain managers can make more proactive decisions. For shippers, consumer-facing analytics guide customer service. That is the foundation of success in supply chains.

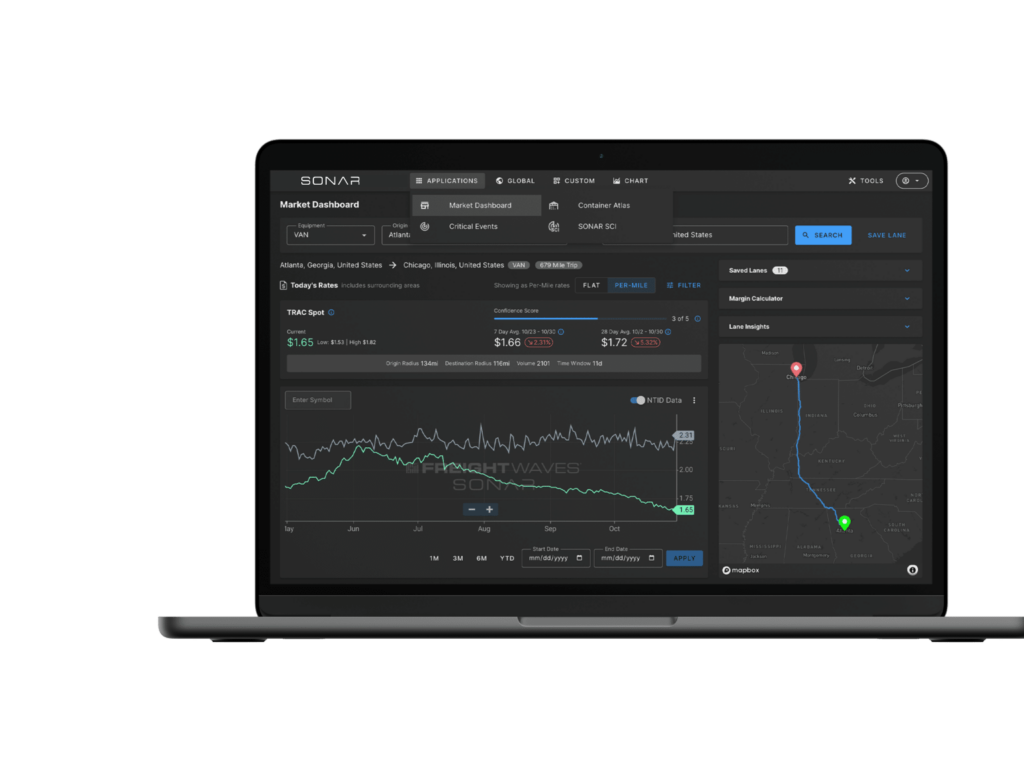

The landscape of supply chain analytics must transcend typical network silos. Effective analytics work across the full shipment lifecycle. Their insights add value through business-to-business and business-to-consumer transactions. That includes the seven analytics uses identified by McKinsey & Company. Regardless, any effective strategy must also work across all freight management systems. FreightWaves SONAR possesses the capability to feed data across your enterprise.

Learn how your company can use freight data analytics by getting a SONAR demo via the button below!