A leading automotive manufacturer was facing challenges in its North American truckload network that resulted in spending more than the market price and still not receiving the levels of service necessary for the operation. Like many manufacturers in the automotive industry, this company relies on high levels of service to ensure the assembly lines remain operational.

The manufacturer was searching for the ability to:

- Improve efficiency within its transportation network

- Reduce costs

- Proactively manage carrier performance risks in its supply chain

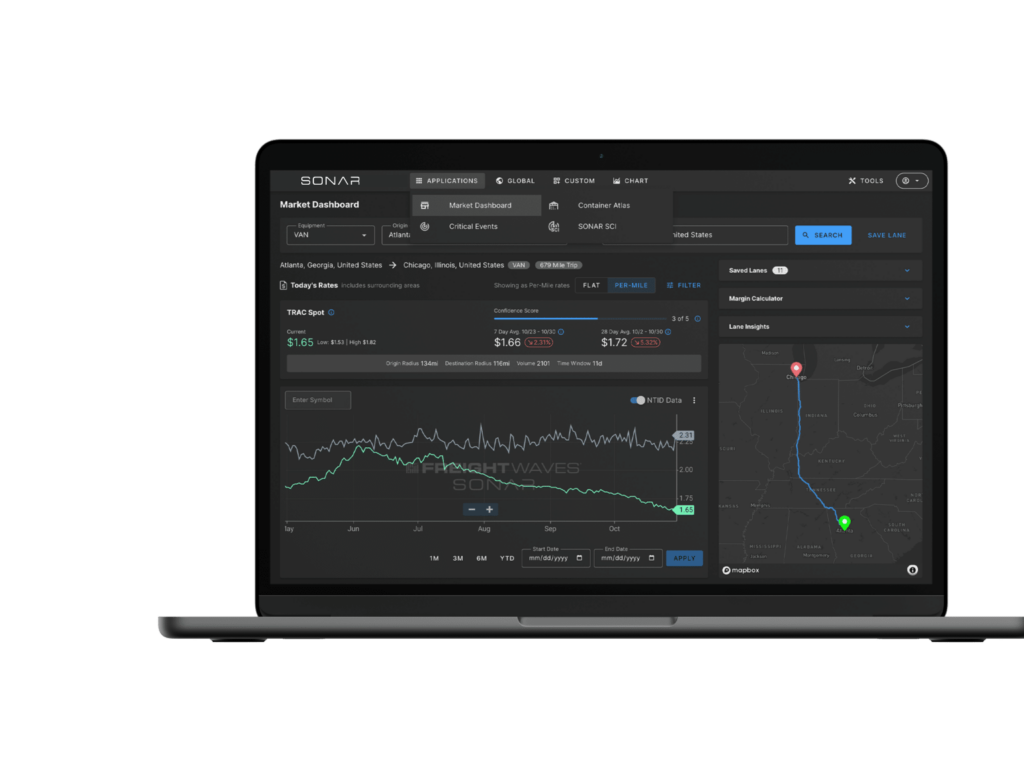

The manufacturer turned to SONAR in order to benchmark itself against the broader automotive industry to identify savings and de-risk its supply chain from service failures related to capacity shortages.

The SONAR and Supply Chain Intelligence (SCI) platforms highlighted where the company could improve efficiencies within its North American transportation network, leading to network optimization, improved negotiations with truckload carriers, an understanding of capacity changes in the market and ultimately uncovering ways to reduce transportation spending.

The automotive manufacturer generated $15 million in transportation savings by adjusting its rates to align with its peers and the overall market rate. At the same time, the manufacturer discovered over 4% of its network was at high risk of service failures, allowing the company to proactively de-risk its network without accumulating service failures along the way.