The ability to unlock freight optimization and gain meaningful insights to monitor, measure and improve supply chain management is more critical than ever. And according to a recent survey of logistics professionals, reported by Supply Chain 24/7, “A combined 61% of research participants indicated that improving forecast accuracy is either ‘important’ or ‘extremely important’ for their organizations. To improve accuracy, many are betting on new technologies like machine learning and demand sensing.” Shippers, logistics service providers (LSPs), carriers and drivers need to know how optimization of freight is evolving in the wake of digital transformation, why it is more than simple freight mode analysis and its implications for maximizing supply chain performance.

When it comes to managing and optimizing freight, several common misconceptions already exist, including:

Now, consider these added challenges in trying to overcome the myths.

The best way forward is to recognize when things go wrong and intervene to yield the best performance.

Existing freight optimization is usually directed at optimizing the specific balance of modes or lanes with a particular carrier. However, data’s ability to aid in freight optimization offers significant advantages and looks far beyond a single carrier, route, shipper, origin, destination, or potential disruptive influence. It is an immensely complex process that continuously evolves and reflects the latest threats and opportunities. Freight optimization is a key performance area for any supply chain head in any industry. This essentially means the moving of products to customers while maintaining desired service levels in the supply chain by determining the most efficient means.

This is so effective that if it is done properly, this can reduce freight costs anywhere from 10% to 40%.

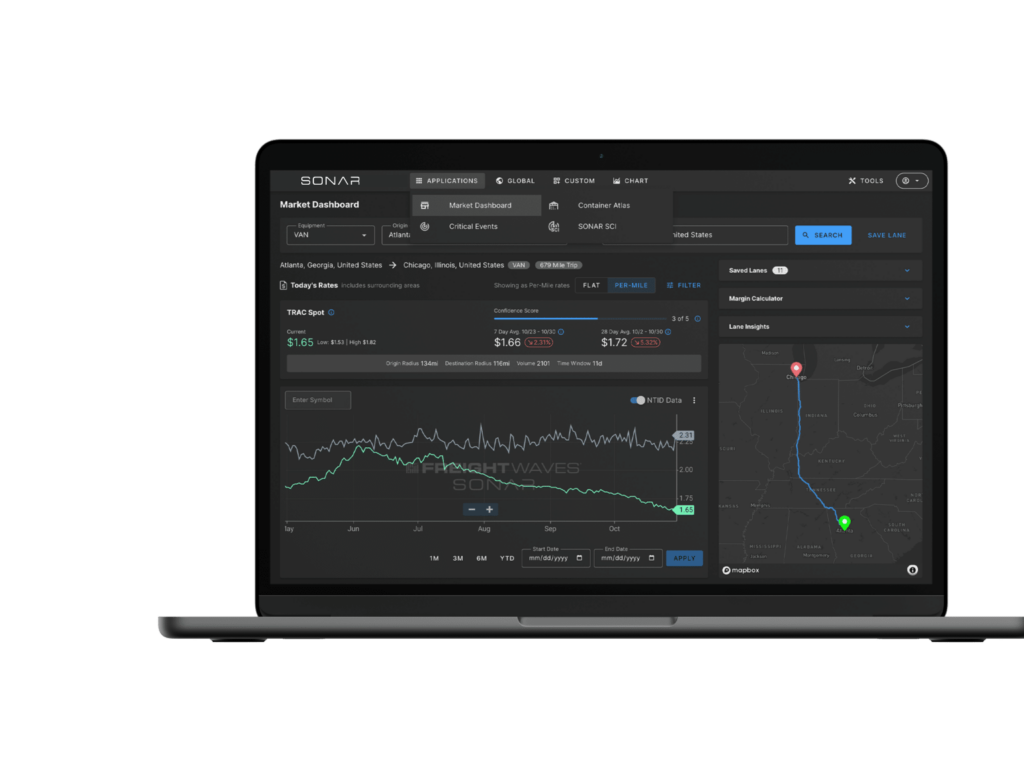

All freight management parties can successfully maximize performance through proper optimization of freight processes. However, optimization of freight can be a topic that harkens anxiety in how a manager goes about the initiative. The transportation manager or broker may have concerns about finding and applying the right resources to properly connect data sets together that also yield meaningfully actionable insights. Such a technical undertaking in-house is likely too cost-prohibitive. As a result, many brokers, shippers and carriers turn to outside resources, like FreightWaves and freight forecasting engines, such as FreightWaves SONAR to make it possible. Still, it helps to have a few best practices to apply performance measurement data to increase freight optimization, including:

Using data and insights

as your guide to freight

bidding negotiations

The adage remains true – performance measurement is the only way to improve anything. While that may not seem like a foreign concept in the global, connected supply chain, optimization of freight protocols remains archaic. It truly doesn’t matter if a company gets the best spot rate or contract freight rate; it’s all about the total landed cost and impact on the business-customer relationship. The best-laid plans for maximizing freight optimization will not work when companies fail to realize the real complexity and scope of capturing and applying meaningful insights. Fortunately, an advanced freight forecasting engine helps achieve those goals. Request a SONAR demo online today.