Each week, you’ll learn about another index found within SONAR, the freight forecasting platform from FreightWaves. This week the Tender Lead Time Index (TLT) that measures the length of time in days between the load being offered and the requested pickup date, is highlighted. Read further to learn what the Tender Lead Time Index is and how freight market participants use the TLT, specifically the Outbound Tender Lead Time (OTLT) Index to measure a freight shipper’s reaction to changes in trucking capacity.

The Tender Lead Time (OTLT/ITLT) Index is a daily index that measures the length of time in days between a load being offered and the requested pickup date. For example, if Shipper A sends a load request on June 8th with a pickup date of June 10th, the load has a 2-day OTLT.

There are two directions that SONAR subscribers may view – the Outbound Tender Lead Time (OTLT) and the Inbound Tender Lead Time (ITLT) indices.

There are additional versions of the OTLT/ITLT by equipment type and length of haul:

Equipment Type:

Length of Haul:

For inbound tender lead times, simply replace the ‘O’ with an ‘I.’

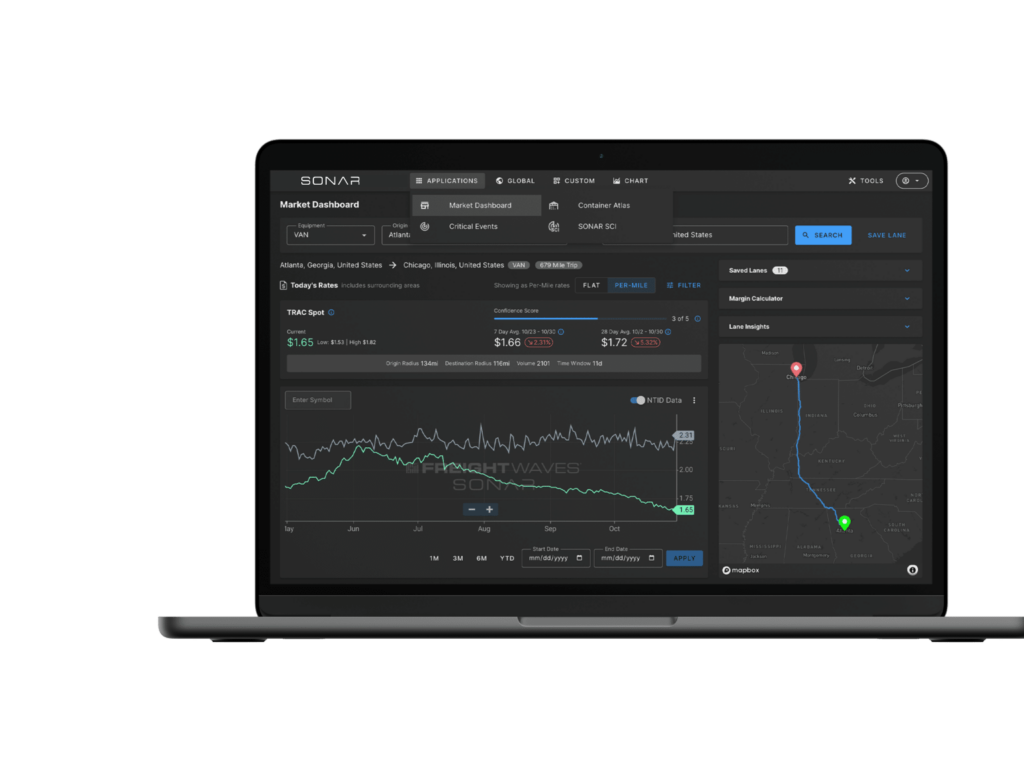

In the image above, note how the OTLT index for the USA (OTLT.USA ticker in SONAR) has remained stable but is trending lower. This indicates that a freight shipper is turning to the spot market, meaning capacity in the freight market is growing tighter.

TLT will help SONAR users understand a freight shipper’s reaction to current market conditions. When a market experiences changes in TLT it can mean:

TLT helps SONAR users understand market conditions from a freight shipper’s perspective. Are shippers experiencing tight or loose capacity issues? Capacity issues can lead to fluctuations in spot freight rates in a market, influencing changes by brokers, carriers and shippers on how they approach a market.

Let’s take a look at how various parties interested in understanding freight shippers’ responses to trucking capacity would use the TLT indices:

Pro Tip: Use OTLT in conjunction with the Outbound Tender Reject Index (OTRI) to understand both shippers’ and carriers’ reactions to the current market conditions.

At the conclusion of 2019, SONAR freight market expert, Zach Strickland used the OTLT in conjunction with the OTRI to gauge the freight shipper response to carriers in the last few months of the year.

His analysis found that freight shipper lead times shrank by 5% on average in 2019 compared to 2018 as capacity was almost guaranteed throughout the year — indicated by the OTRI falling from over 15% to around 5% early in the year.

Strickland noted, “Through the back half of 2018, the average lead time was 2.74 days, while the average for the last six months in 2019 was 2.6 days. The decline in lead time may not seem like a big deal to most who are unfamiliar with freight or transportation, but lead times are an indication of freight shipper perception; that perception has changed over the past two months.”

In addition to measuring a freight shipper’s concern over trucking capacity, several factors influence lead time changes, with two of the main ones being:

These two reasons listed have a short-term impact on lead time. While the main focus of this blog post is how freight shippers are responding to capacity conditions what occurred in 2019 in response to the softer conditions was more of a long-run development.

Looking at the chart, there is an obvious connection to increasing lead times around holidays, when shippers push as many orders as they can prior to leaving their businesses. Many of these orders are for the days following the holiday. The problem with this practice is that it leads to demand-side gluts, where multiple days of shipments are scheduled to ship all at once. Many carriers are either on home time — an industry term for when drivers are off the road — or stuck awaiting their customer’s return so they can get unloaded in the days following holidays. Trucking spot rates increased 3% to 8% in the days leading up to the major national holidays in 2019, and we can expect to see the same for 2020.

In all circumstances listed, increasing lead times are grounded in shippers’ perceived need for capacity or expectation of carrier availability — and both are tied to the basic concept of scarcity. Over the past 12 months, shippers have given carriers less time from order to requested pickup date because capacity has been consistently available or less scarce.

Scarcity not only impacts price but also behavior. The holiday shopping season is a perfect example of scarcity impacting behavior. Shoppers across the country place orders for gifts weeks ahead of when they need the item when most other times of the year a trip to the store the day or week before will suffice. Freight shippers cannot order trucking capacity too far ahead of time, however.

The problem with ordering capacity too far into the future is the number of things that can interfere with planning, such as weather events, customer delays, and traffic. Any delays can throw carrier schedules into disarray, making planning exponentially difficult after about three days.

Ideally, carriers want as much lead time as possible, but the reality is that they cannot plan reliably too far out into the future and shipper cancellations or reschedules increase significantly after about 5 days.

In uncertain times, freight market participants need certainty to stay ahead of the freight market and understand the freight demand occurring in each participant’s most important lanes. The premier freight forecasting engine, FreightWaves SONAR, allows participants to benchmark, analyze, monitor and forecast freight demand and costs. SONAR ensures more proactive responses to the market, the ability to provide a solid customer experience by offering transparency, as well as to make faster, more informed decisions. Get a demo of SONAR to see what the platform can do for you.