At its annual Investment Community Meeting in April in Tampa, Florida, Walmart’s management team took the opportunity to lay out an ambitious transformation of its supply chain. Walmart U.S. CEO and President John Furner explained how the retailer was digitally combining its ambient, perishable and e-commerce supply chains, which were built separately and in parallel in the physical world.

Connecting demand signals, order flows and inventory data across those chains enables new algorithmic decision-making that can optimize Walmart’s supply chain for flexibility and responsiveness.

“When Walmart started, customers came to stores, and they bought general merchandise and consumables,” Furner said. “So we built an ambient supply chain that served stores. As our store footprint grew, that network grew. When we added grocery and supercenters, we built a perishable supply chain — with buildings to handle cold and frozen items. That one also serviced stores. Then came e-commerce. So we built another fulfillment network and partnered with carriers to move products from [fulfillment centers] to customers’ homes. And we layered in pickup and delivery too — from our stores.

“We got by serving customers with these resources … but they weren’t connected. They operated in parallel, and they weren’t flexible. They were each effective at completing the task they were built to perform. Now that’s changing. We’ve reengineered our supply chain networks to connect all the assets we have,” Furner said.

In taking the opportunity to make strategic investments in digital supply chain tools during a market downcycle, when capacity is loose, freight costs are low and customer demand looks shaky, Walmart was bucking the trend among large shippers. More accurately, Walmart was once again ahead of the curve.

Since 2022, transportation costs in all modes have plummeted from their pandemic highs, and many transportation managers and supply chain leaders are satisfied with the year-over-year progress that’s already been achieved.

After all, when trucking carriers are rejecting just 3% of the shipments that shippers tender them, there are fewer fires to put out, and less pressing need for new digital capabilities.

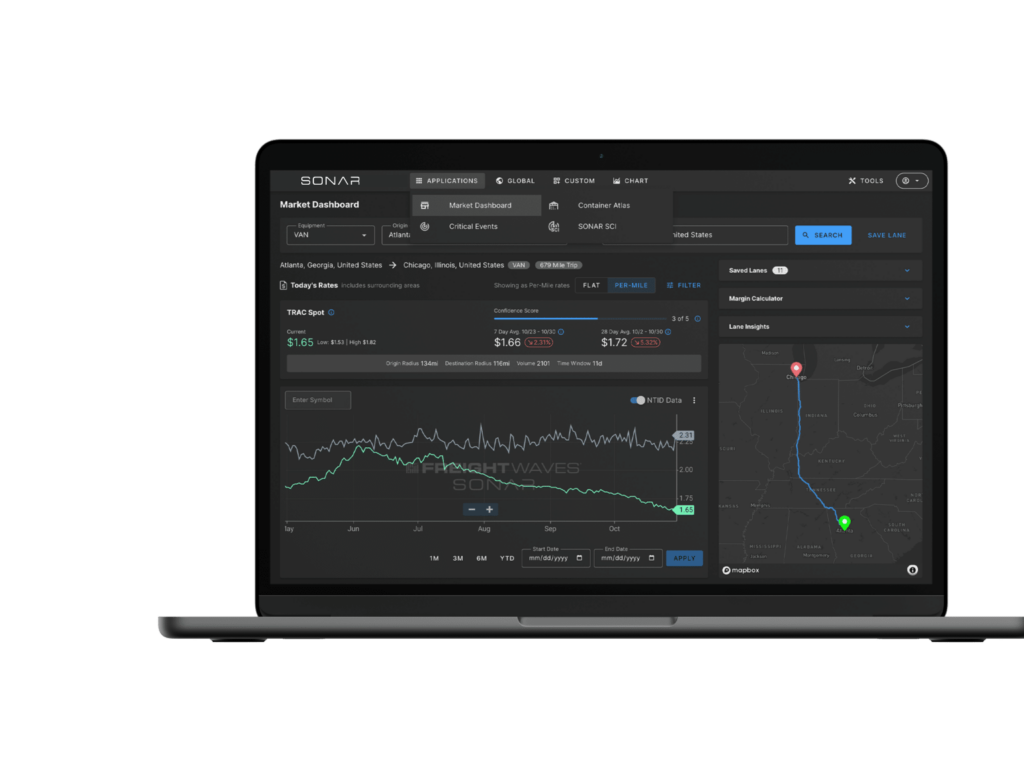

(The Outbound Tender Reject Index measures the percentage of load tenders rejected by carriers. To learn more about FreightWaves SONAR, click here.)

PwC’s 2023 Digital Trends in Supply Chain Survey found that supply chain executives have been unable to prioritize strategic digital investments, even though the vast majority acknowledged that they needed additional tools to derisk their supply chains.

“Executives continue to focus more on basic, near-term priorities and challenges in their supply chains and less on actions and investments that can help transform supply chains and create long-term value,” PwC found.

The attitudes that the supply chain executives shared in the PwC survey, when taken together, paint a picture of companies that get caught up in tactical, day-to-day problems, make reactive decisions to emerging risks, and as a result, fail to realize the full value of their digital supply chain investments.

Let’s walk through the numbers: Only one-third of executives said that “increasing resilience” is a top objective when investing in supply chain technology; “few” executives planned to introduce additional automation or use technology to enhance execution in the next 24 months. On the other hand, 86% of the respondents agreed that their companies should invest in technology to identify, track and measure supply chain risk. A large majority of respondents recognized that upskilling employees was vital to successful technology investments, but only 7% made digital upskilling a top priority. Finally, the kicker: 83% of executives said that their supply chain investments haven’t fully delivered expected results.

As a group, the supply chain executives believed that mitigating risk was necessary but said their companies didn’t prioritize resilience. There were suggestions that companies didn’t follow through with implementation, training and change management after the supply chain technology investments that they did make. One can infer that hasty, reactive investments made in the heat of a capacity crunch or supply chain disruption are rarely executed with the thoroughness needed to deliver the desired ROI.

That makes sense: Large organizations need time to evaluate their needs and find the right solution. Multiple stakeholders across the organization, from senior supply chain leaders to transportation managers and IT professionals have to be brought into alignment to understand the problem and how to address it. Then come procurement processes, including consuming market research and expert analysis, issuing requests for proposals, evaluating vendors, and negotiating contracts— all before the deal is signed. Enterprise software sales cycles alone can take six months.

Then, after the supply chain technology solution has been purchased, it’s time to begin implementation and all of the change management involved in realizing the solution’s ROI. Even the smoothest, best-planned API integration that introduces a new data point or feature into your team’s workflow still needs training and change management to be successful. When those buying decisions are rushed due to a crisis or sudden shift in management priorities, essential pieces of that support and follow-through slip through the cracks.

We know that it doesn’t take long for the freight market to flip: Trucking spot rates have spiked 25% in under 60 days, faster than retailers and manufacturers can react.

Waiting until you have an urgent need for a supply chain technology solution to start the procurement process for it almost guarantees that the solution will arrive too late for the immediate crisis and that its implementation will be hasty and incomplete. But that’s why so many supply chain executives don’t get the full results they expected from their technology investments.

Walmart, on the other hand, has a well-earned reputation for innovation, capital efficiency and strategically transforming the practice of supply chain management into a growth engine for the business. As management reminded Wall Street at its Investment Community Meeting down in Tampa: Everyday Low Prices are only enabled by Everyday Low Costs.

Be like Walmart: Think strategically and long term, past the current crisis or doldrum. The question of the day is how companies can manage risk in their supply chains with technology that allows them to be more responsive to changing conditions, whether on the supply or demand side.

We’d love to talk about this with you. To schedule a consultation about FreightWaves SONAR, click here.