One of the most crucial aspects of logistics management is the process of trade agreements and annual negotiations. However, this is also one of the most overlooked and glossed-over parts of the process as well. Reaching mutually beneficial service level agreements (SLA) or trade agreements depends on the access and utilization of current logistics data and a decent amount of preparation. Proactive planning is among the most effective weapons logistics managers have in their arsenal. It is something that needs to be practiced more often when it comes to planning and predicting freight rates.

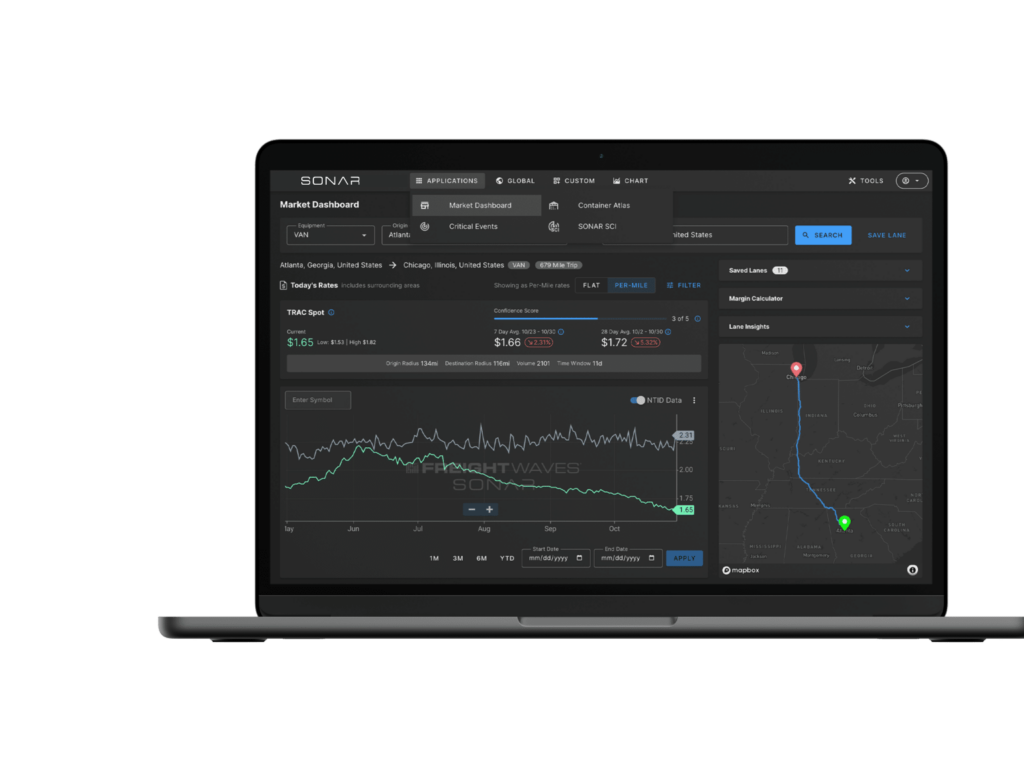

For instance, using the trends and seasonality within the Outbound Tender Rejection Index, shown above, logistics coordinators can create responses to RFPs based on like a higher all-in rate. And that’s especially true when considering new carriers or using other modes of transportation.

Within the modern supply chain, SLAs are the contracts that lay out the terms and specifics of a partnership and shipping agreement. Far too often, there is a severe lack of real-time logistics data to work with during this process. This lack of insight affects network visibility and makes it difficult to know what current transportation rates are, what trends are rising and falling at any time, and how logistics data is changing over time. All of this makes it much more challenging to find the best partnerships in RFP processes. It is nearly impossible to manage SLAs and routing guide compliance practically and successfully without access to sound data. Thus, proactive planning, data collection, analytical methods, backtesting and practical applications are critical for growth within the supply chain network.

Many businessmen and women are familiar with the 80/20 concept when it comes to workloads. The idea is that 80% of the work often is completed by 20% of the team. A similar ratio also exists when it comes to logistics negotiations. As highlighted by LinkedIn, a staggering 80% of bargaining is preparation, analysis, data review and planning before any meeting or discussion occurs. This leaves 20% of the work focusing on the actual conversations and back and forth. The more prepared logistics managers are with goals and protocols, understanding logistics data and preparing for counter-arguments, the greater their negotiating power. And that’s a meaningful advantage in an industry where growth remains subjective and constantly under the threat of other competitors.

Providing the highest quality of service, along with the best options and personalization, will set providers apart and highlight their worth to current and potential customers. Supply chain leaders should follow a few tips for using logistics data in trade agreements to improve service quality and performance, including the following:

Accessing and responding effectively to data and market demands will help transportation managers meet and exceed customer service quality expectations.

Logistics data is changing all of the time, so real-time analysis and communication are critical for the modern supply chain network. To find the best partnerships, be successful with RFP processes, and maximize delivery success rates, data must be at the heart of the network. Utilizing current logistics data analytics and a willingness to commit to good preparation will help ensure continued growth. And having actionable intelligence that considers the local and national markets helps boost your understanding of the industry.

Meanwhile, that amounts to helping shippers to justify requests for new contracted rates in mini-bids. And it helps carriers or brokers justify increased rates to their clientele as well. Request a FreightWaves SONAR or a SONAR SCI Lane Acuity demo to boost your current RFP processes by clicking the respective button below.