Unlocking better freight cost management continues to redefine the standards around the globe. As companies look for ways to maximize value, the use of freight business intelligence, including actionable indices and meaningful trucking rate market metrics, comes to the forefront of the topic. And according to Kyle Taylor and Luke Falasca on an episode of #WithSONAR, “There’s a big difference between knowledge and intelligence. Knowledge is knowing what is the best rate on a lane. But that’s just one part of freight business intelligence. The next piece is intelligence, which is knowing how the market conditions on that lane are moving and how that impacts the rate.” Therefore, it’s imperative to look at how freight business intelligence powers decision-making across freight management and all end-to-end supply chain processes.

Outdated data leads to inefficiencies that arise from a failure to recognize and intervene promptly. And in today’s world, any delay or missed opportunity could be the kiss of death for customer experience. Whether they realize it or not, many freight market participants are relying on stale and narrow data to make critical freight decisions. Stale, outdated data has been a hallmark of freight management until recently. More freight technology providers are understanding that in order to optimize freight budgets, speed in decision-making requires real-time data feeds, not lagging data that is 7 to 10 days (or older).

Exceptions occur in shipping every day, and as the old adage says “it’s not what happens to you, but how you respond.” Access and use of real-time actionable insights provide you with faster, optimized decisions that can make or break a customer’s experience or a shipper’s budget.

Real-time data to power freight business intelligence is often spoken about today in the realm of shipment tracking and recently in mitigating freight loss or damage. We see this in new products such as sensors to give real-time data about shipment conditions. According to a FreightWaves article discussing Shock, which monitors other environmental conditions, such as temperature, humidity and pressure, “The more visibility you can get into your shipping process, the better. Shock recorders and other live data trackers are revolutionizing shipping by giving shipping and logistics professionals an unprecedented level of visibility into the shipping process.”

When a company lacks accurate and real-time data, all insights and recommended courses of action fail to consider the impact on the overall supply chain. Even worse, using outdated data can lead to more disastrous consequences, such as failure to consider headhaul demand in specific lanes and leaving shippers with little, if any, carriers available for bookings.

Obtaining real-time data and advanced freight business intelligence forms the basis for actionable decision-making. Instead of relying on assumptions, companies achieve a higher level of service. They can better accommodate disruptions within the market. And they can perform more efficiently. Access to real- or near-time freight business intelligence provides an action plan to improve asset utilization and transportation capacity procurement.

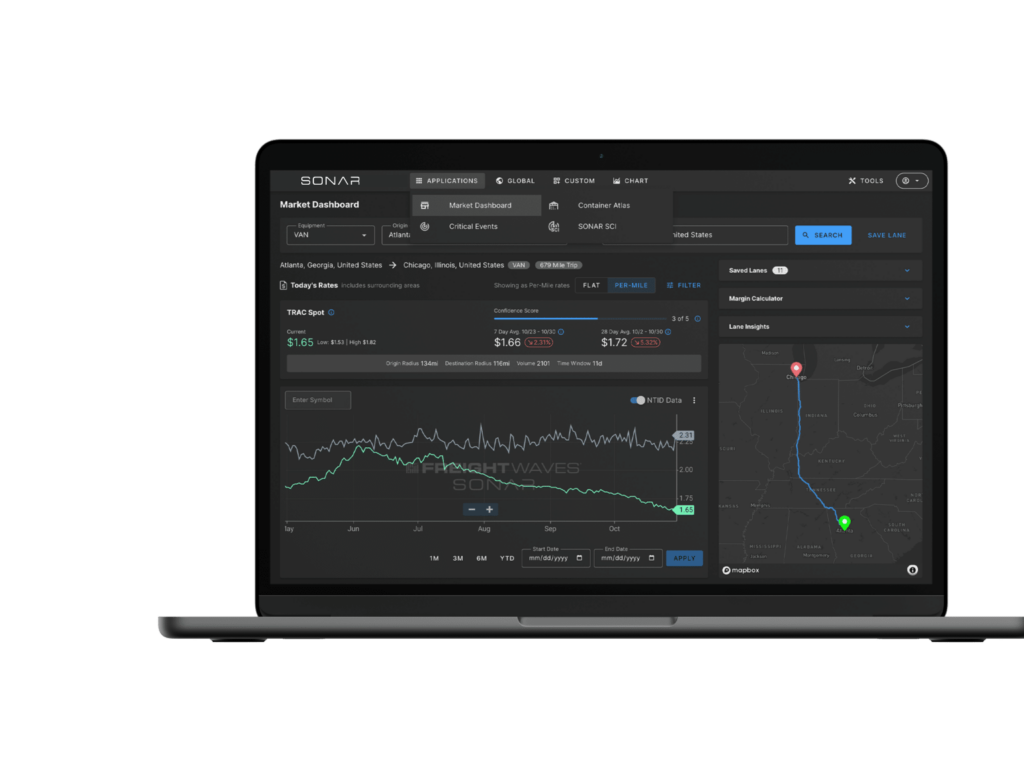

Further, with FreightWaves SONAR, users have access to datasets that use algorithms and correlations to help determine whether a load tender may be accepted or rejected in your lanes or markets, or if you need to conduct a new freight bidding practice, and much more. Freight business intelligence continues to build value in a self-propagating cycle – driving better decisions as more real-time data sets are fed into a platform. However, unless these large datasets are displayed and explained in ways that make sense, and can guide actions to take, that cycle is subject to error and severe profit losses.

There are many ways to apply freight business intelligence in freight forecasting and management. Start by picking the low-hanging fruit to keep total expenses in check. But additional opportunities rest within improvements in workflows, regardless of freight management segment. So, look to these added best practices to apply freight business intelligence to improve operability irrespective of the segment:

Freight business intelligence is not just a passing trend. It is the future of freight management. Since supply chains generate new data sources through a relentless push for automation, now is the ideal time to rethink operations and apply business intelligence. More importantly, business intelligence tools, such as SONAR, are more affordable than ever and based on subscription models. In other words, the software-as-a-service (SaaS) narrative returns and proves that all companies can finally deploy business intelligence without breaking the bank.

Request a SONAR demo to start learning more about how your company can apply freight business intelligence data in your supply chain today.