Today’s modern advances in eco-friendly, green practices create an environment where businesses must be conscious of their practices. This becomes especially significant for the carbon footprint of companies in transportation, logistics and supply chains, including the added expenses associated with reefer during the warmer months. After all, it amounts to increased energy use and effectively increased emissions from somewhere. Regardless, reducing the impact on the environment while also keeping consumer loyalty and boosting efficiency can be tricky, but is possible.

One way to lower costs over the short- and long-term lies in the use of rail transportation. Trains transport multiple units simultaneously, reducing the amount of fuel needed. Reducing fuel lowers the amount of emissions released, thus decreasing the carbon footprint. And ultimately, eliminating the need for excess trucks on the road helps the carrier costs overall and allows for available resource management.

The supply chain relies on tactical transportation management and the ability to minimize any unnecessary delays. Some delays exist in the form of stop-and-go traffic. Optimizing the routes for trucks will remove some of those additional and time-consuming stops.

Important to the optimization of transportation, route optimization also diminishes the emissions strain on the environment and the carbon footprint. Transport Topics believes more companies look to improving sustainability daily with more companies prioritizing ESG initiatives in everyday operations than ever before.

Warming up a vehicle in the winter or cooling it down during the summertime increases environmental strains by idling. Emissions are still released if a truck sits without moving. Large trucks hold significant responsibility for the pollution in the air and expand the carbon footprint. Including limits or guidelines for idle time within your routing guide will help decrease travel time and educate drivers, so they can prepare for potential hurdles.

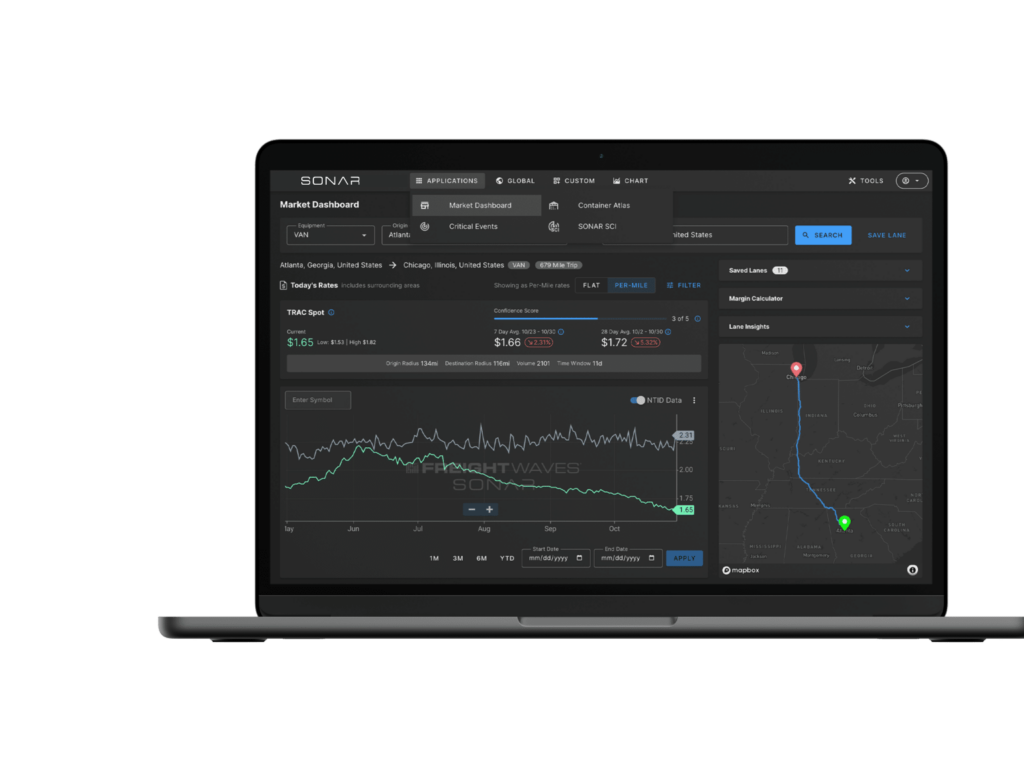

Tracking real-time data proves beneficial to all levels of the transportation industry. The data reveals the most cost-effective ways to transport goods, thus reducing the supply chain industry’s carbon footprint. Although rail transportation can be more cost-efficient, it rarely works for the end-to-end supply chain. Therefore, sometimes intermodal shipping can minimize cost while utilizing more than one transportation method.

Consumers want their products on time, as do businesses. Utterly reliant on on-time delivery for some customers, the supply chain industry must deliver. If this does not happen, supply chain management might run the risk of returns, increasing overall transport costs. Trucks on the road for the same shipment twice expands the carbon footprint left by the industry. Proactive planning significantly decreases the risk of returns.

The ultimate answer to eliminating deadhead and unnecessary trips for trucks lies in market data. The market data reveals freight accuracy. The more accurate data becomes, the more issues diminish. Deadheading is not only dangerous, but also costs companies valuable time, money and increases its carbon footprint by not hauling anything.

The key to improving the logistics behind the supply chain and decreasing the carbon footprint burdening the environment rests upon integrating more steps. These steps lessen the time trucks and other transport modes unnecessarily plague the roads, rails, waters and skies. Utilizing lockers or pickup centers creates a way to shift, change or store trucks for the next mile.

Achieving carbon footprint reductions all comes down to having the right data at your fingertips to continuously improve. And now, FreightWaves SONAR is following that path forward with existing environmental data and big ideals on the horizon in development. In the interim, request a FreightWaves SONAR demo to get started.