Global supply chains suffer from limited visibility and a general want for supply chain intelligence in carrier sourcing, freight tendering and all other processes. According to Derrick Steiner of Digitalist Magazine, “Today’s leading companies are working very hard to be intelligent enterprises, capable of harnessing the power of end-to-end experience and operational data, to connecting their demand chain with their customers, who are social, mobile and shop in many channels, to their supply chain. This is incredibly challenging, considering today’s global supply chains are built on a foundation of increased complexity, globalization, outsourcing, trading partners, geopolitical tensions, trade wars, and risk. Fully 70% of companies say their supply chain is either very or extremely complex and only 6% of companies have full visibility within their supply chains. All of these and many other challenging factors have resulted in an ever-extending supply chain footprint, one holding onto inventory 8% longer than it did 30 years ago.” The need to advance processes to enable proactive freight management leads to one outcome – the absolute need to use artificial intelligence (AI) and machine learning to predict freight rates. And supply chain leaders need to know a few things about how these advancements impact supply chain intelligence, particularly efficacy and productivity.

Poor supply chain visibility remains a top problem for most supply chains. As reported by Forbes, up to 69% of supply chains lack full visibility. And 56% experience supply chain disruptions annually. Of course, no disruption comes close to those that have been experienced to date in 2020. But that principle does allude to another issue. A lack of visibility amounts to an inability to mitigate risks and survive disruption.

Consider this example. As e-commerce peak season ramps up, more organizations will see available drivers and capacity dwindle. Thus, freight rates are going to continue climbing. Without supply chain visibility, a retailer cannot realistically move freight to other markets to take advantage of trucking capacity. And total landed costs go through the roof. Imagine how that scenario might change if supply chain intelligence that leveraged AI and machine learning was a bit more involved. It would allow companies to predict rates and needs.

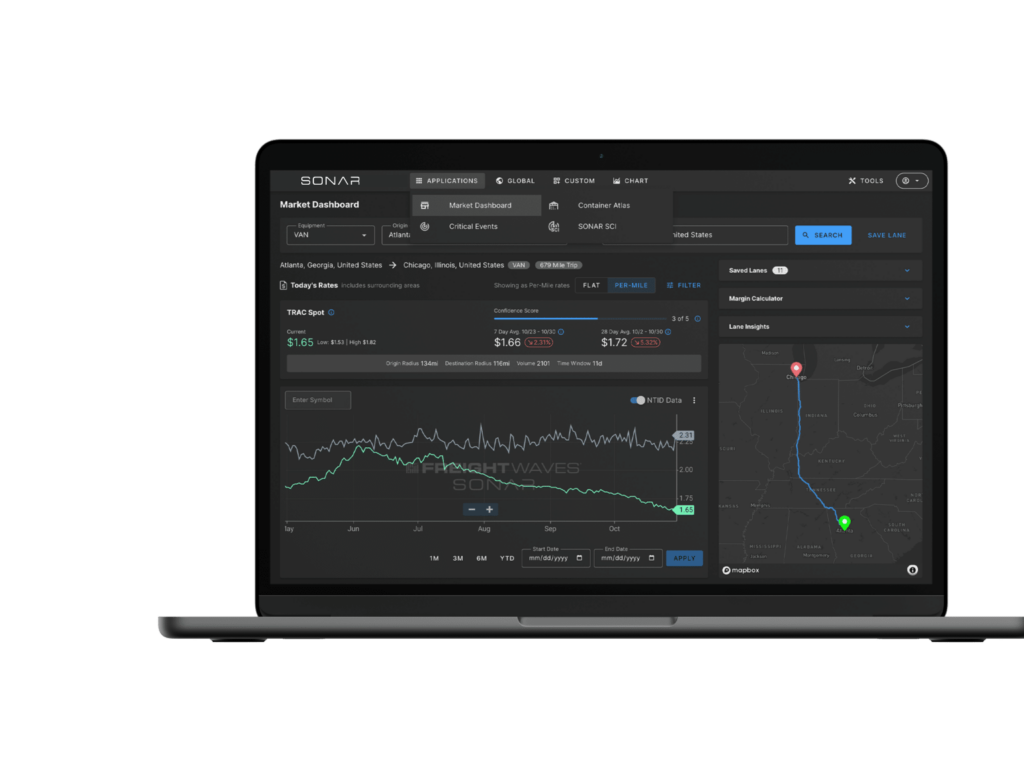

Yes, AI and machine learning build on algorithms to isolate historical trends and derive a likely transportation rate. But this is 2020. And the past data trends are obsolete and rapidly becoming more so. Companies simply do not have the luxury to make last-minute decisions for basic transportation moves. However, AI can provide a pathway toward more proactive, responsive management strategies. Machine learning turns the raw data into actionable insights through big data analytics, such as recognizing when tendering activity increases, seen in SONAR as the Inbound or Outbound Tender Volume Index (ITVI and OTVI), and when tender rejections increase, seen as either Outbound Tender Rejection Index (OTRI) or Inbound Tender Rejection Index (ITRI). With that in mind, AI could act on that information to derive more meaningful insights and genuine supply chain intelligence. Now, what’s a meaningful insight?

Consider this example.

Meaningful insight is a prescribed series of actions necessary to make a significant dent in total logistics spend or delays. In other words, supply chain intelligence reveals how a company might leverage market data to reallocate assets, increase rates offered at the time of tendering, and/or lower the risk of rejections. Of course, even those capabilities hinge on AI to digest, interpret and act upon data.

AI and machine learning have a common goal – the increased automation of logistics. When a company’s employees spend less time analyzing data, they can focus more on supply chain needs – such as moving freight, producing items for retail, or sourcing drivers. It’s that simple. And those functionalities also give rise to increased demand forecasting capabilities. “When inventory lags demand, companies suffer losses. AI is ramping up efficiencies in network planning and predictive demand, allowing merchandisers to become more proactive. By knowing what to expect, they can adjust the number of vehicles and direct them to locations where maximum demand is expected. This leads to lower operational costs,” wrote Dan Khasis in SCB. Therefore, companies can focus more on their actual workload and spend less time managing freight – a real win-win.

Of course, brokers and carriers – whose businesses are wholly transportation – will still be involved. But having access to that information upfront, clearly and concisely presented as indices and insights, amounts to faster management and getting the most profits from all loads across all modes and through all lanes. That enables management by exception and the continued growth of supply chain intelligence to avoid rework and streamline processes.

All supply chains want efficiency and productivity gains. The combination of AI-driven processes, machine learning, and autonomous logistics management helps turn that want into a reality. And part of the path to success rests on an AI-powered transportation data engine that ingests data from thousands of sources and creates actionable insights. Find out more about the possible insights that could help your business by requesting a SONAR demo online today.