Effective supply chain management and logistics RFP processes depend on an accurate measure of the health of the business and the market. Big data provides an opportunity to gain those insights, especially during volatile freight markets. As further explained by Grainger, “Big Data gives businesses the ability to monitor products with laser-like focus as they move through their supply chain in real-time. Businesses no longer have to guess where their items are or whether their shipments will arrive on time. Big Data tracks every detail, from where it is to the status of each shipment.” Thus, supply chain leaders need to know how to apply that data with these top 10 supply chain KPIs.

The asset utilization of any supply chain company is a critical factor in decision-making. It is calculated by dividing the existing assets in use by the sum of all used and unused assets. As asset utilization increases closer to 100%, it represents less capacity within an organization and an opportunity to expand the business.

Comparable to the need to track assets, supply chain management companies can also follow the number of carriers used versus all available carriers. More carriers lead to a protective effect in supply chain management.

Tracking the total volume shipped and tracking that volume by carrier are other ways companies can measure business health. Knowing total volume requirements is also essential to guiding RFP processes and asking for volume discounts. By breaking that information down by carrier, companies can further refine their truckload RFP processes to get the best deal possible.

Among supply chain KPIs, tracking the cargo volume and average value or cost per load is crucial. It is simply the sum of all freight under management (FUM) divided by the total number of loads.

Freight claims, damage and losses are also critical supply chain KPIs. As the risk of damage or an adverse event occurring increases, companies can recognize the need to either consider outsourcing work to another carrier, requiring additional proof of delivery, or taking other steps to secure freight. It is calculated by dividing the total number of such claims by the total number of shipments and deliveries.

The perfect order rate is relatively simple in the list of top supply chain KPIs. It includes the percentage of orders that contain the right product, are shipped with the right freight carrier, and arrived at the perfect time. It is that simple.

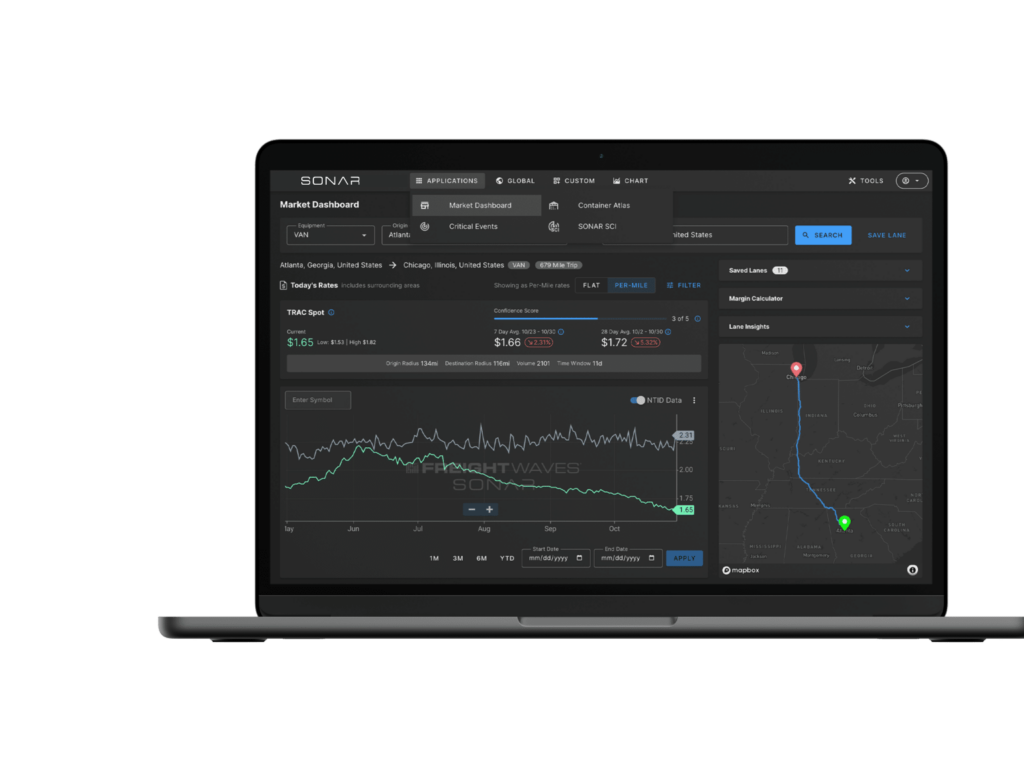

Measuring current fuel costs against market trends is another way to benchmark company performance. And in fact, SONAR-provided lane data for fuel rates can help companies ensure they actually pay competitive prices for fuel surcharges.

Managing freight rate averages by lane compared to market trends is another opportunity to benchmark performance. It all goes back to diversifying the carrier base and exploring new opportunities to conserve freight expenses.

Tracking the average revenue gained per load allows for continuous performance management of front-line workers and gauging the average net value gained or lost from all transactions.

And lastly, tracking the average distance traveled by load, or average length of haul, helps companies to recognize when it may be necessary to open additional offices, onboard new lanes, or expand into new carrier networks.

The right supply chain KPIs freight professionals should know must add value. They should be actionable, meaning companies can apply that data to improve performance, contracts, other business-to-business partners, and customer experiences. Fortunately, leveraging a freight forecasting platform that compiles freight data from across the market, such as FreightWaves SONAR, can make the difference between leveraging the right KPIs or only going about business as usual. Schedule a SONAR demo online to learn more.